- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

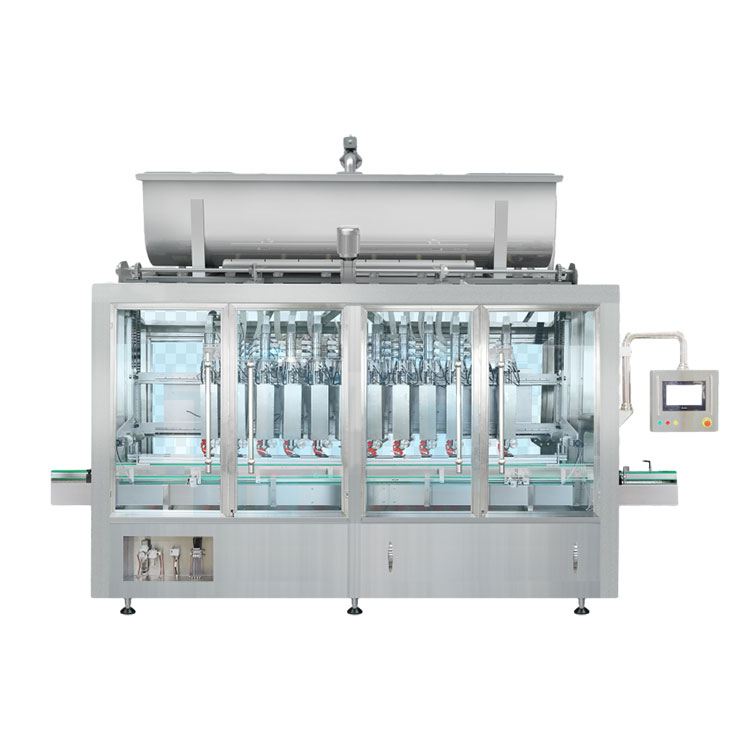

20-50L Fully Automatic Filling Machine

As a professional manufacturer, Somtrue is committed to producing high quality 20-50L fully automatic filling machines. The company has advanced production process and technical strength, as well as experienced team, can tailor solutions for customers to meet the needs of different sizes of liquid filling. 20-50L fully automatic filling machine with its stable and reliable performance and advanced automatic control system, enjoy a high reputation in the industry. We always adhere to the principle of quality first, and constantly optimize the production process and quality management system to ensure that every equipment meets the highest standards.

Send Inquiry

20-50L Fully Automatic Filling Machine

(The appearance of the equipment will vary according to the customized function or technical upgrade, subject to the physical object.)

As a professional manufacturer, Somtrue is committed to producing high quality 20-50L fully automatic filling machines. The company has advanced production process and technical strength, as well as experienced team, can tailor solutions for customers to meet the needs of different sizes of liquid filling. 20-50L fully automatic filling machine with its stable and reliable performance and advanced automatic control system, enjoy a high reputation in the industry. We always adhere to the principle of quality first, and constantly optimize the production process and quality management system to ensure that every equipment meets the highest standards.

As a manufacturer, Somtrue has won the trust and support of customers with its excellent product quality and perfect after-sales service. The company adhering to the concept of honesty and integrity, excellence, and strive to provide customers with efficient and reliable 20-50L fully automatic filling machine, and provide a full range of technical support and solutions. We will continue to make unremitting efforts to continuously improve product quality and technical level to meet the growing needs of customers, provide customers with better products and services, and jointly create a better future.

20-50L Fully Automatic Filling Machine overview:

The filling head of this equipment is used to ensure the filling speed and accuracy. During filling, the filling head is inserted into the barrel mouth to fill on the liquid level. The filling process of the gun head produces no foam, and the filling head is designed. After the filling, the filling plate is out to prevent the packing and delivery line body.

The equipment has manual and automatic operation conversion device, which can realize single bucket filling; the equipment has manual and automatic speed regulation function.

When filling, the filling speed is automatically adjusted for different material pressures. Automatic filling filling head diving has overload protection function.

The weighing system adopts high precision weighing instrument and toldo weighing sensor to ensure the filling accuracy. In addition, the system has anti-corrosion and anti-overload protection devices. The sensor is explosion-proof, with convenient installation, disassembly and maintenance. The weighing system controls the accuracy through high precision weighing instrument, and the accuracy of small flow can be fine-tuned.

Main technical parameter:

| Explosion-proof grade:E | xd II BT4 |

| Outline dimension:((Length, X, width, X, height) mm: | 3,500 X2000X3500 |

| Bearing weight: | 100.000Kg |

| Minimum Scale Value: | 5g(0.005Kg) |

| Filling range: | 20.000∼50.000Kg |

| Filling head: | 6 heads |

| Filling speed: | 300-600 b / h (according on specific material flow characteristics) |

| Filling accuracy: | ± 2 / 1000 (0.2%) |

| Filling material: | polyurethane |

| Filling head model: | filling on the liquid level |

| Material contact material: | SS304 |

| Gasket: | PTFE |

| Power supply power: | AC380V / 50Hz; 3kW |

| Air source pressure: | 0.6MPa |

* Automatic liquid connection tray

Automatic tray prevents contamination by liquid dripping after closing the filling head.

The liquid tray operates automatically through the cylinder expansion.

The liquid plate can be easily cleaned and replaced without any tools, and the liquid plate is enlarged.

* performance characteristics

Automatic set of gross weight and reset function

Fast crude filling, slow speed fine filling

2 gear flow control system

The filling system contains the "compensated weight for free product falling" function, which can be set by the operator.

If the filling head stops filling, but the product weight is still insufficient, it can be automatically fed.

* Clean design

Design of weighing sensors and components to prevent contamination from product overflow.

Even if the product overflows, the liquid enters the sink.

The connecting tank is a drawer design, the operator cleaning easily.

All product contact parts are made of SS304 material.

* Safe area equipment

We believe that through the efforts and cooperation of both sides, we can achieve mutual benefit and win-win results and jointly create bright prospects for cooperation. If you have any further needs or questions, please feel free to contact us, we will be happy to serve you!