- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

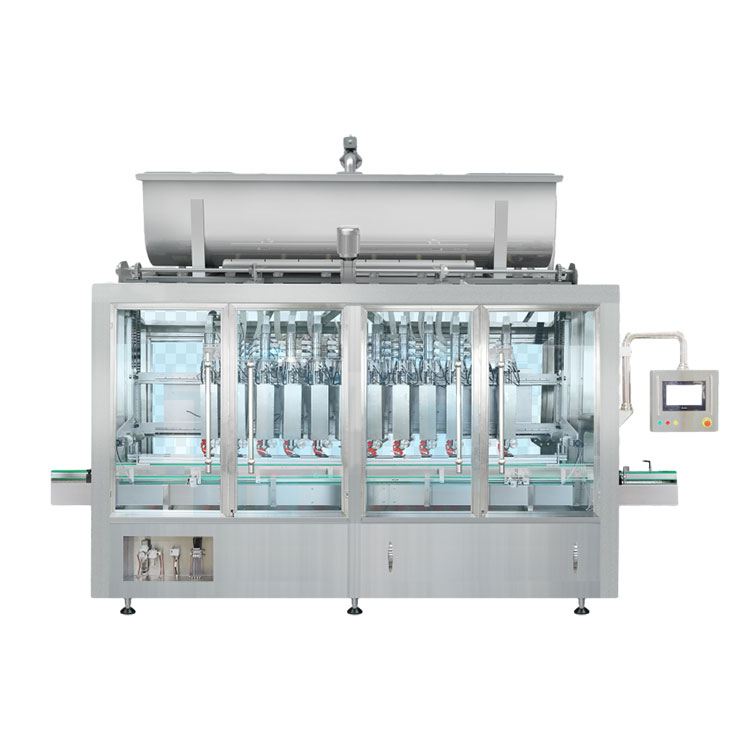

1000L Fully Automatic Filling Machine

Somtrue is a manufacturer focusing on the production of high quality 1000L fully automatic filling machines. We have advanced production processes and technical strength, as well as an experienced team, committed to providing customers with reliable solutions. The product is widely praised in various industries for its excellent performance and stable quality.

Send Inquiry

1000L Fully Automatic Filling Machine

(The appearance of the equipment will vary according to the customized function or technical upgrade, subject to the physical object.)

Somtrue as a manufacturer, always uphold the concept of excellence. We not only provide high quality 1000L fully automatic filling machines, but also provide comprehensive pre-sales consultation and after-sales service support. Whether it is the installation and commissioning of equipment, or routine maintenance and troubleshooting, we will respond positively and provide technical support and solutions in a timely manner. The cooperation between us and customers is a long-term stable partnership, we will be dedicated to provide customers with quality products and services, and jointly promote the development and prosperity of the industry.

Equipment overview:

An intelligent packaging system designed for liquid packaging of IBC barrels. Using mechanical positioning, IBC barrel can realize automatic opening, automatic diving, automatic filling, automatic leakage, automatic cover and other whole process of automatic packaging.

There are recycling buckets, new bucket open irrigation rotation, old bucket filling need to manually open the cover lock cover.

The filling main engine part adopts environmental protection frame with visual window. The electrical control part of this machine is composed of PLC programmable controller, weighing module, etc., with strong control ability and high degree of automation. With the function of no barrel filling, no filling of the barrel mouth is not allowed, to avoid the waste and pollution of materials, so that the electromechanical integration of the machine has been a perfect performance.

The working principle of weighing is used to realize the control of the filling amount. The filling valve opening time is controlled by the programmable controller PLC, and the material flows into (or transported through the pump feed) to the container. The filling department of this machine realizes fast filling and slow filling through double thick and thin pipeline, and the slow filling flow is adjustable. At the initial time of filling, the double pipeline is opened at the same time. After the filling period, the diving cylinder rises to the barrel mouth position, the crude pipeline is closed, and the thin pipeline continues to fill slowly until the set overall filling volume. Automatic spin cover is performed at the end of filling.

The equipment has a weighing and feedback system, which can set and adjust the fast and slow filling volume.

The touch screen can simultaneously display the current time, equipment running status, filling weight, cumulative output and other functions.

The equipment has the functions of alarm mechanism, fault display and prompt processing scheme.

The filling line has the function of interlock protection, the filling automatically stops, and the filling automatically when the filling is in place.

Main technical parameters:

| Outline dimension(length*width*height)mm: | 3210×2605×3000 |

| Suitable for barrel type: | IBC barrel |

| Filling station: | 1 |

| Material contact material: | 304 stainless steel |

| Main material: | carbon steel spray plastic |

| Filling mode: | filling under the liquid level |

| Production speed: | about 8-10 barrels / hour (1000L; according on the customer material viscosity and incoming method) |

| Weighing range: | 0-1,500 kg |

| Filling error: | 0.1% F.S. |

| Scale value: | 200g |

| Power supply power: | AC380V / 50Hz; 10kW |

| Gas supply source: | 0.6MPa;1.5m³ / h interface: φ 12 hose |

We look forward to working with you to create a more prosperous future! We will continue to provide high-quality 1000L fully automatic filling machines, and continue to optimize and innovate to adapt to changes in market demand. We believe that through mutual cooperation and win-win results, we can achieve greater development and achievements. Let us work together to explore the market, promote the progress and development of the industry, and bring more value and opportunities to customers.