- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

200L 1000L Visual Fully Automatic Filling Machine

As a 200L 1000L Visual Fully Automatic Filling Machine manufacturer, Somtrue always puts quality first and continuously optimizes the production process and quality management system. We strictly control every link to ensure that each 200L 1000L visual fully automatic filling machine can meet the highest standards. We understand the performance and reliability requirements of our customers, which is why we not only invest significant resources in R&D and innovation, but also work closely with our partners to ensure that our products meet the diverse needs of our customers.

Send Inquiry

200L 1000L Visual Fully Automatic Filling Machine

(The appearance of the equipment will vary according to the customized function or technical upgrade, subject to the physical object.)

Somtrue is a professional manufacturer, committed to providing global customers with better products and services. Our 200L 1000L visual fully automatic filling machine is not only well received in the domestic market, but also won wide recognition in the international market. Through unremitting efforts and continuous innovation, Somtrue continues to improve its technical level and production capacity to meet the growing needs of global customers. We believe that through the efforts and cooperation of both sides, we will create a better future! Whether it is an existing customer or a new partner, we look forward to growing together with you and achieving greater success and achievement. Let's meet the challenge together, create greater value for customers, and share the development and progress of the industry!

200L 1000L Visual Fully Automatic Filling Machine overview:

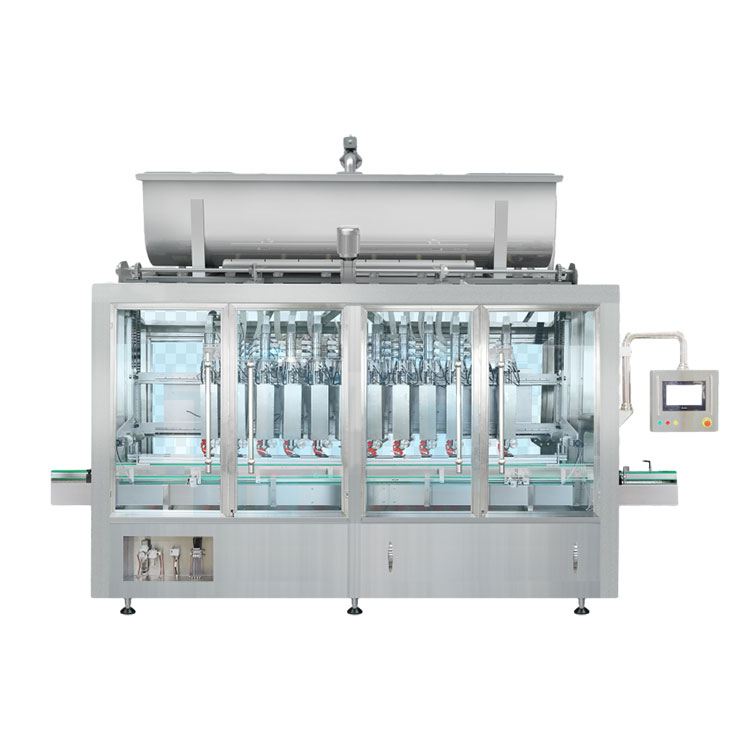

An intelligent packaging system specially designed for 200L barrels in explosion-proof environment for 200L barrel (including tray) packaging. Using visual search mouth, it can realize the automatic packaging of 200L barrel of automatic opening, automatic diving, automatic fast filling, automatic leakage, automatic sealing thread cover and other whole processes.

The filling main part adopts environmental protection frame, which can view the window, and automatically moves the door in and out of the bucket, which can form a closed space when filling. The electrical control part of this machine consists of PLC programmable controller, weighing module, visual system, etc., with strong control ability and high degree of automation. With the function of no barrel filling, no filling of the barrel mouth is not allowed, to avoid the waste and pollution of materials, so that the electromechanical integration of the machine has been a perfect performance.

The working principle of weighing is used to realize the control of the filling amount. The filling valve opening time is controlled by the programmable controller PLC, and the material flows into (or transported through the pump feed) to the container. The filling department of this machine realizes fast filling and slow filling through double thick and thin pipeline, and the slow filling flow is adjustable. At the initial time of filling, the double pipeline is opened at the same time. After the filling period, the diving cylinder rises to the barrel mouth position, the crude pipeline is closed, and the thin pipeline continues to fill slowly until the set overall filling volume. Automatic spin cover is performed at the end of filling.

The equipment has a weighing and feedback system, which can set and adjust the fast and slow filling volume.

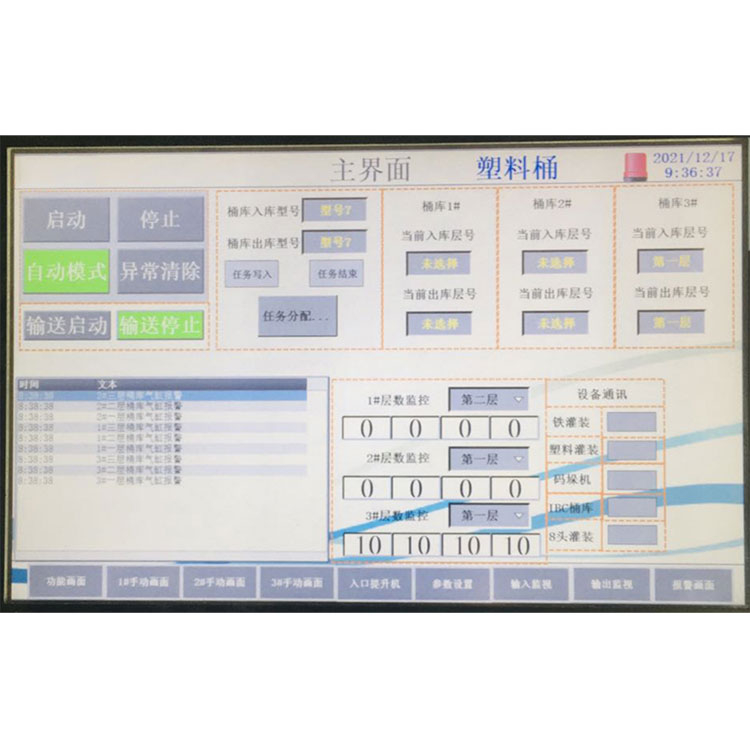

The touch screen can simultaneously display the current time, equipment running status, filling weight, cumulative output and other functions.

The equipment has the functions of alarm mechanism, fault display and prompt processing scheme.

The filling line has the function of interlock protection, the filling automatically stops, and the filling automatically when the filling is in place.

This machine is equipped with the whole cover, the single side of the bucket is open, maintain natural ventilation; the rest is closed structure, with Windows, and equipped with small ventilation for manual control.

This machine is fully closed cover, with pressurization interface, can microcharge the equipment, reduce the external gas into the equipment.

Main technical parameters:

| Explosion-proof type: | Exd ii BT4 |

| Outline dimension (length, width and height) mm: | 2400*2800*3000 |

| Suitable barrel type: | 200L iron barrel (4 barrels / tray) |

| Weighing range: | 0-1,500 kg |

| Filling accuracy: | ± 200g (200L barrel meter) |

| Scale value: | 200g |

| Power supply power: | AC380V / 50Hz; 10kW |

| Gas supply source: | 0.6MPa;1.5m³ / h interface: φ 12 hose |

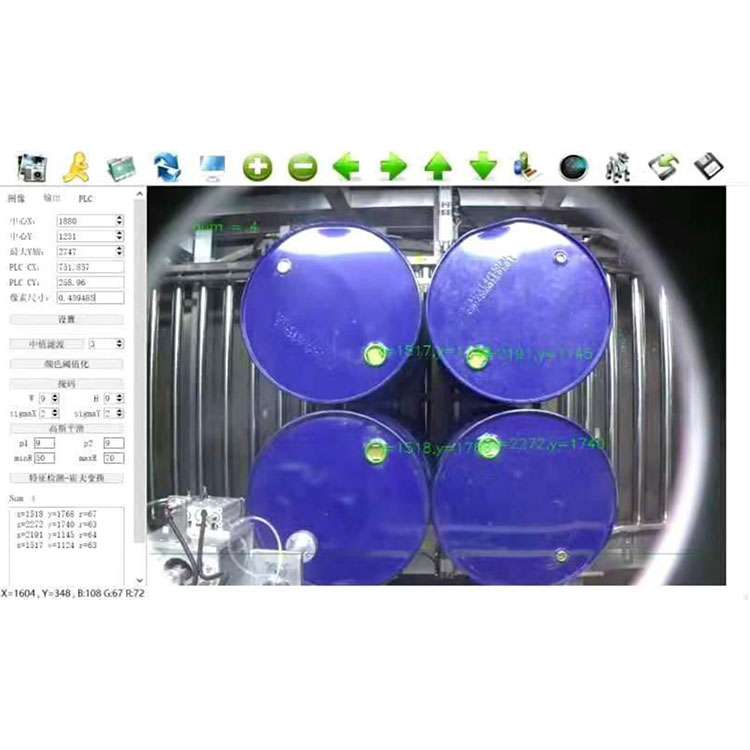

Visual positioning system

Vision: using industrial intelligent camera, loaded into the visual explosion isolation machine box to work. From the intelligent camera, and the PLC control coordinate moving system points the filling gun at the barrel port.3 D coordinate moving system: guide rail system and explosion-proof deceleration motor.

Major function:

Automatic search: visual positioning, coordinate moving system search, filling gun drop filling.

Fast and slow double-speed automatic quantitative filling: to ensure the filling accuracy and production capacity;

Filling form: filling on or under the liquid level;

The pneumatic base valve is always wide open, slowly add the front end flow limit-slow down the flow rate of the filling gun outlet;

Design of liquid cup-minimize the leakage of residual liquid after perfusion;

Automatic and manual quantitative filling-easy operation and maintenance;

Automatic peeling function-overcomes the influence of inconsistent weight factors of filling container on accuracy;

Value point adjustable-quantitative filling adapted to multiple weight ranges;

Automatic diagnosis, fault alarm-improve the reliability of the system work;

Safety interlock-bucket in place, spray gun down; fill gun top barrel return;

Self-locking control-test the nozzle before filling;

Product setting storage-can store up to a variety of different products weight set value and related perfusion parameters;

Tolerance detection-automatic detection of the filling error;

Touch screen-Chinese interface, intuitive, convenient setting.

Alarm alert-Accurate to the point of failure.

Automatic control system

The whole line is composed of multiple PLC systems, which can be controlled independently controlled and interlock each other. It has the functions of system self-inspection, fault display alarm, accuracy, speed, output, etc. Each system has its own man-machine interface, and all parameters can be operated on the man-machine interface. Provide a detailed pipeline control process flow chart and logic diagram.

Can store filling material type, quantity batch, date, weight per barrel, storage time and other recording functions

Filling system and open spin cap system

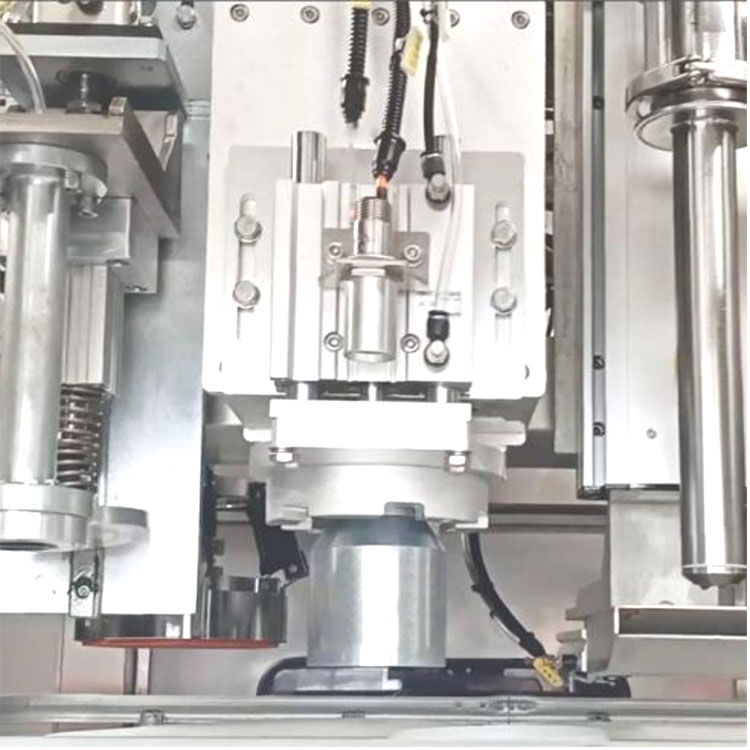

Filling gun head: in the form of external blocking, will automatically dive to the barrel mouth (bottom of the barrel) during the filling, and automatically rise after the filling. The filling gun head is a hollow design, and the material can be purged after the gun head is closed to prevent material splashing.

The lower part of the filling gun head is provided with a cylinder extending liquid plate. After the filling, the filling head rises and the drain plate extends to prevent the material from polluting the packing and conveying line body. The liquid connecting disc is designed for freehand disassembly, which can be disassembled without tools and is convenient for cleaning.

Open cover, spin cover part: using the company's patented technology, can package the rotary cover head and the barrel surface vertical, and can be smooth, easy to open the cover and spin cover, do not damage the cover, do not hurt the cover, tight cover sealing degree is high.

Touch screen and weighing system

Material filling parameter setting and operation through the touch screen operation, simple and intuitive, and with temperature display, fault diagnosis and alarm, prompt function. It has the memory storage program function, can store multiple sets of parameters, and can view historical data. Can automatically calculate the measurement deviation, and can be named for different programs, change different specifications or change the production capacity, only need to adjust different parameters, can improve the work efficiency. The weighing system adopts the famous American brand sensor to ensure the filling accuracy. In addition, the system has the function of oil protection, and the sensor is convenient to install, remove and repair.

The scale table has a protective function, when the head of the gun barrel, the gun head automatically returned. And protected with maximum filling time.

safety interlocking

Safety Interlock at the Feed Site:

Install button number 1 and 2 at feeding. When the tray is placed and transported on the top, press the button # 1, and then the assembly line carries the No.1 mark and delivers the tray to the No.1 filling equipment.

Once again, when the tray is placed and transported on the tray, press the No.2 button. Then the assembly line carries the No.2 mark and delivers the tray to the No.2 filling equipment.

When the no. 1 filling is discharged, the assembly line will carry the No.1 completion mark, and will not go to the No.2 filling equipment to the next station.

Filling Safety Interlock:

satety exit:

When the security door opens, pause the current action;

After the security door is closed, the abnormal access control is removed, and the filling continues to complete the normal operation.

Diving interlock:

Outside the mouth of the filling bucket, an abnormal downpressure alarm is generated, and the filling head rises to the original position and solved by manual intervention.

Filling overweight:

Filling test filling overtime, the whole machine stop filling, alarm, manual intervention to solve.

Filling plugging alarm

The camera takes abnormal alarm

Abnormal incoming and outgoing material alarm

Somtrue has a design and manufacturing team full of creativity and professional knowledge. Our team members are experienced and have extensive industry knowledge and technical expertise. Whether it is product design, process planning or equipment manufacturing, we pay attention to detail and strive for excellence. We believe that it is the unremitting efforts and superb skills of this professional team that make Jiangsu Shangchun able to provide high-quality products and services to meet the diversified needs of customers.