- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

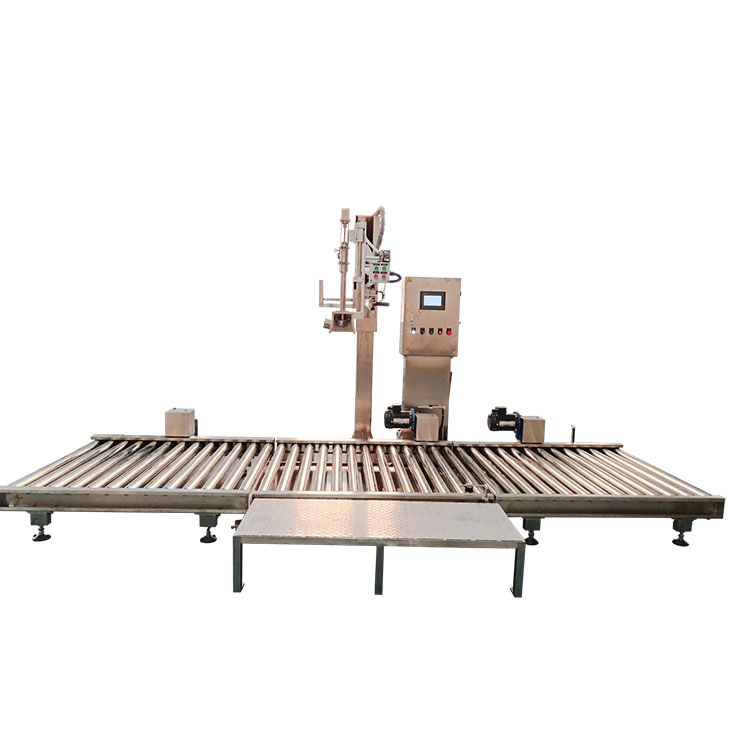

200L Barrels And IBC Barrels Share A Fully Automatic Lithium Battery Liquid Filling Machine

This machine is specially designed for 200L four barrels a pallet, tons of chemical raw materials packaging intelligent packaging system, used for 200L drums (including pallets), tons of drums packaging. The use of visual search, can achieve 200L four barrels a pallet, tons of barrels of automatic cover opening, automatic diving, automatic fast filling, automatic leakage, automatic capping and other whole process automatic packaging.

Send Inquiry

Equipment overview

Suitable for lithium battery liquid packaging.

This machine is specially designed for 200L four barrels a pallet, tons of chemical raw materials packaging intelligent packaging system, used for 200L drums (including pallets), tons of drums packaging. The use of visual search, can achieve 200L four barrels a pallet, tons of barrels of automatic cover opening, automatic diving, automatic fast filling, automatic leakage, automatic capping and other whole process automatic packaging.

The main part of the filling machine adopts environmental protection frame, can be Windows, automatic lifting and sliding door in and out of the barrel, and can form a closed space when filling. The electrical control part of the machine is composed of PLC programmable controller, weighing module, vision system, etc., which has strong control ability and high degree of automation.

The thick pipe is closed, and the thin pipe continues to fill slowly until the set overall filling amount is reached. Automatic capping at the end of filling.

The touch screen can simultaneously display the current time, equipment operating status, filling weight, cumulative output and other functions.

The equipment has the functions of alarm mechanism, fault display, prompt processing scheme and so on.

The filling line has the function of interlock protection for the whole line, the filling of missing drums automatically stops, and the filling of drums automatically resumes when they are in place.

The machine is provided with a cover of the whole machine, and the single side of the inlet and outlet barrel is open to maintain natural ventilation; The rest are closed structures with Windows and small fans equipped with manual control of forced ventilation.

The machine is a fully enclosed outer cover, with a pressurization interface, which can micro-pressurize the inside of the equipment and reduce the external gas entering the inside of the equipment.

Main technical parameters:

| Filling station: | simplex (visual search, opening, filling, capping); |

| Search mode: | visual search bucket mouth; |

| Function description: |

drip plate at the head of the gun; The bottom of the filling machine is provided with a liquid tray to prevent overflowing; Connected to the liquid pan for waste collection and treatment: the gun head is equipped with a cleaning bypass valve, and the plc is set up to clean the program, which can realize the one-click cleaning function. |

| Production capacity: |

about 20-25 barrels/hour (200L meter; According to the customer's material viscosity and incoming materials) ;About 6-8 barrels per hour (IBC; According to the customer's material viscosity and incoming materials); |

| Filling error: | ≤±0.1%F.S; |

| Index value: | 200g; |

| Applicable drum type: | 200L drum; container |

| Sealing gasket material: | PTFE; |

| Power supply: | AC480V/60Hz; 10kW |

| Working environment temperature range: | -10℃ ~ +40℃; |

| Working environment relative humidity: | < 95%RH (no condensation); |