- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

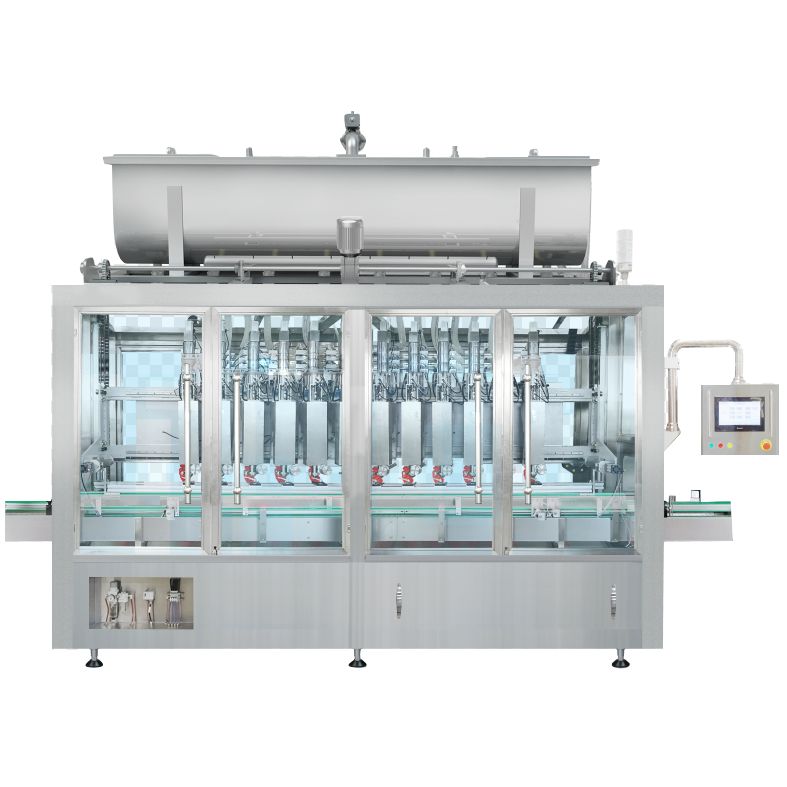

5L Barrel Automatic Chemical Raw Material Filling Machine

The 5L Barrel Automatic Chemical Raw Material Filling Machine part of the machine realizes fast filling and slow filling through the double throttle cylinder. At the beginning of filling, after the double throttle cylinder is converted to stroke 1, it is quickly converted to stroke 2 for fast filling. After filling to the fast filling set amount, the submerged cylinder rises to the barrel mouth, and the double throttle cylinder is converted to stroke 1 to continue slow filling until the set overall filling amount is reached.

Send Inquiry

Process Flow:

The 5L Barrel Automatic Chemical Raw Material Filling Machine part of the machine realizes fast filling and slow filling through the double throttle cylinder. At the beginning of filling, after the double throttle cylinder is converted to stroke 1, it is quickly converted to stroke 2 for fast filling. After filling to the fast filling set amount, the submerged cylinder rises to the barrel mouth, and the double throttle cylinder is converted to stroke 1 to continue slow filling until the set overall filling amount is reached.

It is the ideal packaging machine for fine chemical industry.

1. The 5L Barrel Automatic Chemical Raw Material Filling Machine adopts programmable controller (PLC) and touch screen for operation control, easy to use and adjust.

2. There is a weighing and feedback system under each filling head, which can set the filling amount of each head and make a single micro adjustment.

3. Sensors, proximity switches, etc. are all advanced sensing components, so that no bucket is not filled, and the barrel blocking master will automatically stop and alarm.

4. The filling head has the function of coarse and fine filling to ensure the filling speed and accuracy. The filling head is equipped with a feeding device, which can catch the floating material after the filling head is closed, so that the material of the filling head does not drop to the barrel, the filling head does not drop, and the filling station is kept clean. The whole filling head gun should be automatically moved up and down and fixed horizontally, and the spray gun should be extended into the barrel during filling to prevent splashing out when the material is thin, and the filling can achieve zero drip.

5. The equipment has manual and automatic point operation conversion device, which can realize single bucket independent metering filling; The equipment has the function of manual and automatic speed regulation. There is no oil spill when the transmission starts.

Main Technical Parameters:

|

Number of filling heads |

2 |

|

Main material |

carbon steel spray |

|

Filling gun size |

DN50 |

|

Measurement error |

20L±20mL |

|

Power supply |

AC380V/50Hz; 3.0 kW |

|

Air source pressure |

0.6MPa |