- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

Products

In China, Somtrue is distinguished among manufacturers and suppliers. Our factory provides Palletising Machine, Strapping Machine, Filling Machiner, etc. Extreme design, quality raw materials, high performance and competitive price are what every customer wants, and that's also what we can offer you. We take high quality, reasonable price and perfect service.

- View as

5L Barrel Semi-Automatic Chemical Additive Filling Machine

This machine is a weighing filling machine with 1-5kg specifications, manual bucket placing, weighing filling and a series of operations. The machine adopts programmable controller (PLC) to control, easy to use and adjust.

Read MoreSend InquiryIBC Barrel Rocker Arm Chemical Raw Material Filling Machine

Rocker arm four-barrel position &IBC barrel sharing filling machine Intelligent packaging system designed for 100-300kg liquid drum packaging, easy to use and adjust, strong control ability. Suitable for filling chemical raw materials of various viscosity levels. It has stable production capacity, simple operation, high production capacity, and is the ideal equipment for large, Sinopec and intermediate enterprises.

Read MoreSend InquiryIBC Barrel Automatic Chemical Raw Material Filling Machine

The filling machine part uses the environmental protection outer frame, can be windowing. The electrical control part of the machine is composed of PLC programmable controller, weighing module, etc., which has strong control ability and high degree of automation. It has the functions of no barrel filling, no filling at the mouth of the barrel, avoiding the waste and pollution of materials, and making the mechatronics of the machine perfect.

Read MoreSend InquiryIBC Barrel Semi-Automatic Chemical Raw Material Filling Machine

This machine is suitable for IBC drum semi-automatic chemical material packaging machine, using the working principle of weighing to achieve the control of filling volume. The material flows into the container by itself (or is fed by the pump) to be loaded.

Read MoreSend Inquiry200L Barrel Automatic Chemical Raw Material Filling Machine

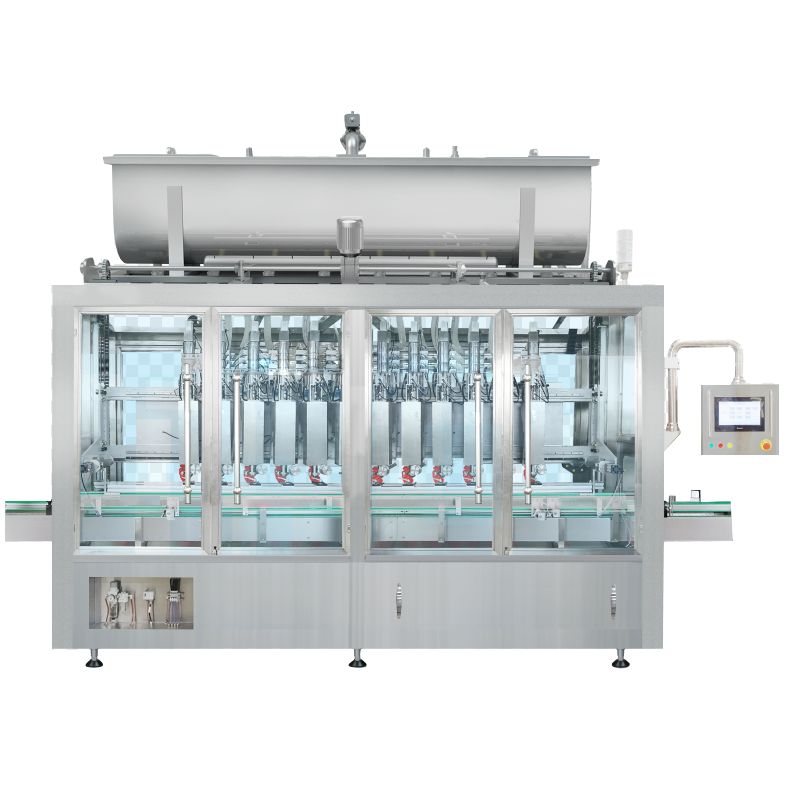

This machine is specially designed for 50-300kg liquid drum packaging intelligent chemical packaging system, with open window, automatic lifting and sliding door easy to close; The whole line can automatically fill the barrel, open and close the door, automatically identify the mouth of the barrel, automatically align the mouth of the barrel, automatically open the lid, automatically fill the barrel, automatically screw the cap, measure the leakage and automatically exit the barrel.

Read MoreSend Inquiry