- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

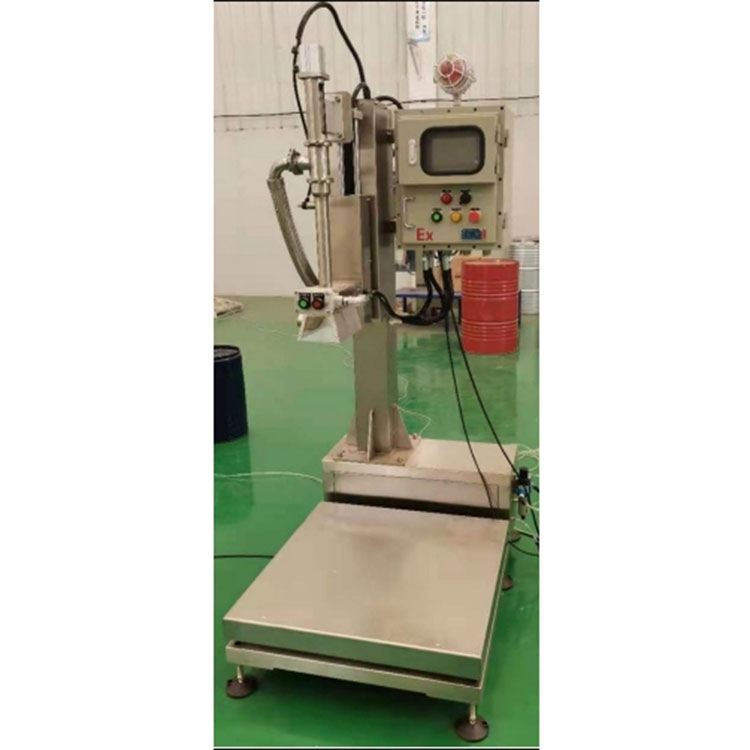

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

200L Barrel Fully Automatic Pharmaceutical Liquid Filling Machine

This machine is specially designed for the 200kg pharmaceutical liquid packaging and intelligent packaging system, the whole line automatically complete the barrel, automatic barrel opening, automatic cover, automatic diving filling, automatic cover, automatic out of the barrel.

Send Inquiry

This machine is specially designed for the 200kg pharmaceutical liquid packaging and intelligent packaging system, the whole line automatically complete the barrel, automatic barrel opening, automatic cover, automatic diving filling, automatic cover, automatic out of the barrel.

The touch screen is used to realize man-machine dialogue, with automatic diagnosis function, operation parameter setting and cumulative shift production, working status display, etc., with automatic tare, cumulative number of barrels, weight, random display of filling amount, automatic zero tracking, automatic correction of fall, over and under, abnormal operation alarm function, high anti-interference ability, reliable work. The system has the function of abnormal self-detection and fault warning. When the measurement is out of tolerance or failure occurs, the system can automatically alarm and close the charging system to avoid material overflow; With the function of the number of barrels and weight accumulation, the data is automatically accumulated after filling. Automatic and manual control operation can be switched, with the parameter memory function of products without specifications, select bucket parameters and filling amount on the touch screen, the operation is simple and intuitive. At the same time display the current time, running status, cumulative output and alarm machine fault display, prompt processing scheme and other functions.

The equipment has weighing and feedback system, which can set and adjust the filling amount.

Filling machine with the whole line interlock protection function, the missing bucket filling automatically stop, the bucket in place automatically resume filling.

Main technical parameters:

Filling station: double station;

Function description: mechanical + photoelectric positioning automatic barrel search;

Automatic opening, filling, capping;

A drip tray is arranged at the head of the gun, and a liquid tray is arranged at the bottom of the filling machine to prevent overflowing;

Nitrogen purge in the gun after filling;

Static electricity when filling, anti-static treatment of the whole line;

Filling gun and connecting pipe heating, temperature 60℃, using metal pad or other methods;

Waste gas treatment: recycling treatment, the whole machine is closed structure, equipped with Windows, access to the lifting door, reserved exhaust interface;

Filling speed: ≥45 barrels/hour (200L meter; According to the customer's material viscosity and incoming materials);

Filling error: ≤±0.1%F.S;

Index value: 50g;

Filling range: 3-300Kg;

Applicable drum type: 200L steel drum;

Material flow material: 304 stainless steel;

Main material: carbon steel spray plastic;

Sealing gasket material: PTFE;

Material interface standard: customer provided;

Gun diameter: DN40 (according to the material viscosity and characteristics, barrel mouth diameter design);

Instrument air interface standard: The user provides G1/2 "manual ball valve with internal thread for quick connection;

Power supply: AC380V/50Hz; 4.5 kW

Required air source: 0.6MPa

Working environment relative humidity: < 95%RH (no condensation);