- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

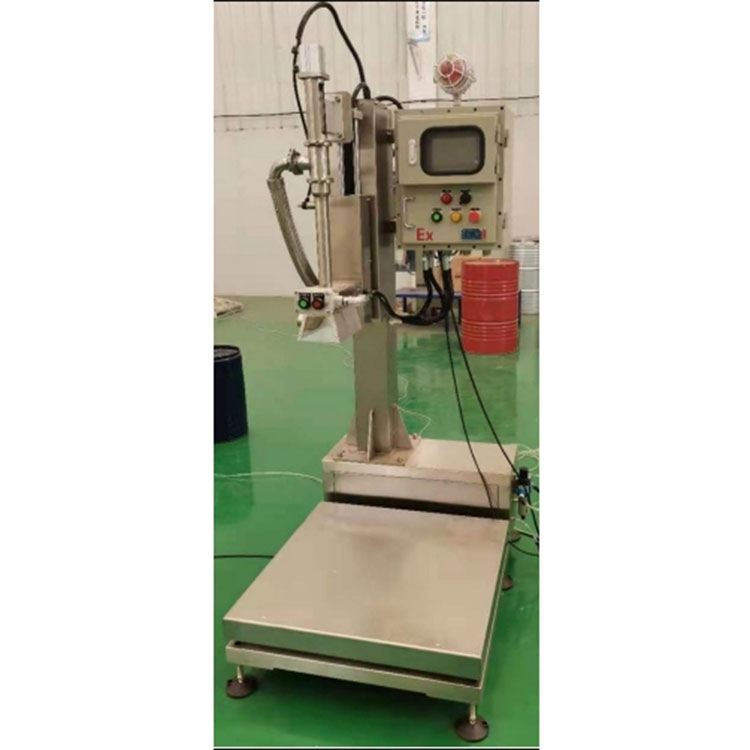

IBC Barrel Semi-Automatic Pharmaceutical Liquid Filling Machine

Ton drum filling machine for 10-1500kg liquid drum packaging and design of intelligent packaging system, use

Send Inquiry

Equipment Overview:

Ton drum filling machine for 10-1500kg liquid drum packaging and design of intelligent packaging system, use

Easy to adjust, strong control ability. It has the characteristics of easy operation, high production efficiency and wide application range. optimum

Used for pharmaceutical packaging of various viscosity levels

It has stable production capacity, simple operation, high production capacity, and is a large, Sinopec, intermediate enterprise VAT packaging

The ideal equipment.

The system has anti-corrosion, anti-overload protection device. The sensor is IP68 protection grade, and the sensor is easy to install, disassemble and maintain.

The touch screen is used to realize man-machine dialogue, with automatic diagnosis function, operation parameter setting and cumulative production, working status display

Main technical parameters:

| Number of filling heads: | 1 (with exhaust gas collection cover; Drip proof cartridge) |

| Filling capacity: | 1000L/ barrel; |

| Filling accuracy: | 0.1%F.S; |

| Rated speed: | 6-12 barrels per hour (1000L; According to the customer's material viscosity and incoming materials); |

| Material contact material: | the flow element is 304 stainless steel, Teflon washer and seal ring; |

| Main material: | 304 stainless steel |

| Weighing device: | maximum weighing 1500kg; |

| Temperature range: | -10~85℃; |

| Power supply: | AC220V/50Hz; 0.5 kW |

| Air source pressure: | 0.6MPa |

| Valve pipe temperature requirements: | > 130℃ (steam purge required) |