- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

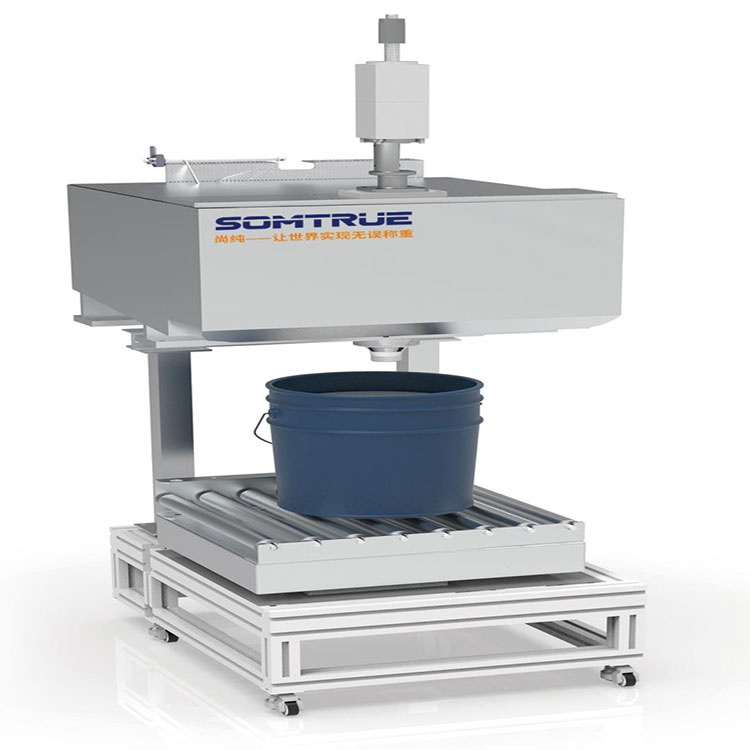

20-100L Barrel Fully Automatic Paint Filling Machine

The weighing system adopts high-precision weighing instrument and Toledo weighing sensor to ensure the filling accuracy. In addition, the system has anti-corrosion and anti-overload protection devices. The sensor is explosion-proof, and the sensor installation, disassembly and maintenance are convenient. The weighing system controls accuracy with high-precision weighing instruments, and the accuracy of small flow rates can be fine-tuned.

Send Inquiry

Equipment Overview:

This equipment is suitable for paint liquid filling machine

The weighing system adopts high-precision weighing instrument and Toledo weighing sensor to ensure the filling accuracy. In addition, the system has anti-corrosion and anti-overload protection devices. The sensor is explosion-proof, and the sensor installation, disassembly and maintenance are convenient. The weighing system controls accuracy with high-precision weighing instruments, and the accuracy of small flow rates can be fine-tuned.

Main technical parameters:

| Weight: | 100.000Kg |

| Minimum weighing value: | 5g(0.005Kg) |

| Filling speed: | 300-600 barrels/hour (depending on specific material flow characteristics) |

| Filling accuracy: | ±2/1000(0.2%) |

| Gasket: | PTFE |

| Power supply: | AC380V/50Hz; 3kW |

* Automatic liquid tray

Automatic liquid tray prevents contamination caused by liquid dripping after closing the filling head.

The liquid receiving tray runs automatically through the cylinder expansion.

* Performance characteristics

Automatic setting of gross weight and reset function

Fast coarse filling, slow fine filling

2 speed flow control system

If the filling head stops filling, but the weight of the product is still insufficient, it can automatically fill the material.

* Clean design

Design load cells and components to prevent contamination caused by product spills.

Even if the product spills, the liquid will enter the liquid reception tank.

The liquid receiving tank is designed as a drawer, which is easy for the operator to clean.

All product contact parts are made of SS304.

* Secure area equipment