- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

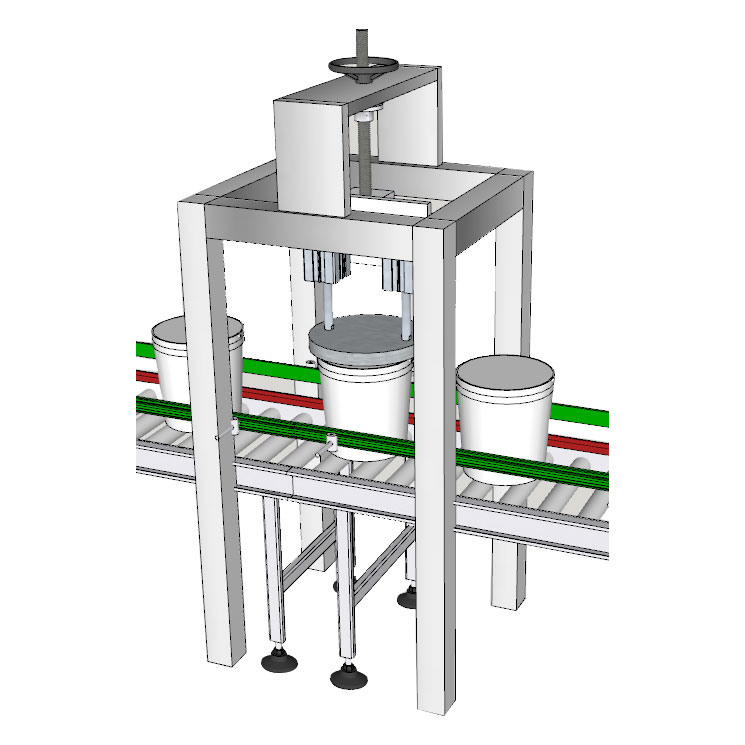

Cap Screwing Machine

Somtrue is a professional manufacturer, committed to providing customers with Cap screwing machine solutions. We know that different industries have different needs for capping machines, so we use our extensive experience and expertise to tailor high quality Cap screwing machineproducts to our customers. With extensive experience and expertise, we provide innovative solutions to our customers. We will continue to make continuous efforts, continuous improvement and innovation to meet the needs of customers, and provide customers with high-quality Cap screwing machineproducts and services.

Send Inquiry

Cap Screwing Machine

(The appearance of the equipment will vary according to the customized function or technical upgrade, subject to the physical object.)

As a leading Cap screwing machine manufacturer, Somtrue focuses on technological innovation and product quality. We continuously invest in research and development and design, introducing advanced technologies and processes to ensure that our cap screwers provide superior performance and stable operation. We are driven by our customers' needs and work closely with them to explore the best Cap screwing machine solutions. Our professional team will fully understand customer requirements, and provide a full range of support and services, including equipment selection, installation and commissioning, to ensure that customers can make full use of our capping machine, and achieve the best production benefits.

Cap Screwing Machine overview:

This Cap Screwing Machine is the latest Cap lifting machine carefully designed by our company, the introduction of foreign advanced technology, with the depth of our company's technical group, so that the overall performance of the product reached the international advanced level, part of the performance has exceeded the best level of similar foreign products, and has been recognized by the world giant companies. Using PLC and touch screen automatic control, with the characteristics of accurate rotating cover, advanced structure, smooth operation, low noise, wide adjustment range, fast production speed, dynamic rotating cover. PLC is equipped with memory function, which can remember a variety of operating parameters at the same time, simple mechanical structure, large space, equipped with safety protection frame, improve the safety performance of the whole machine.

The torque effect control system of the rotating cover head is configured to ensure the rotating cover effect and avoid the injured cover: the rotating cover head is installed with clutch device, the rotary cover is loose and adjustable, when the bottle cap is tightly rotated, the clutch clutch, to avoid the phenomenon of the injured cover and extend the service life of the rotating cover head;

The speed of bottle feeding, rotary cover, bottle transfer, top cover and capping can be adjusted in the touch screen to avoid the phenomenon of bottle dumping and blocking and improve the working efficiency; the bottle clip material is flexible and suitable for most shapes of containers, which eliminates the phenomenon of damaged bottle and bottle injury; the mechanical guide device with high performance and reliability ensures the smooth lid entering and gentle scraping, and ensures the accuracy of taking and placing the lid.

During normal startup, the host with no bottles and few bottles does not work and works automatically after the conditions are met; after blocking the bottle, the host stops down automatically and works automatically after the conditions are met. When there is no cover, the host stops automatically and works automatically after the conditions are met.

The replacement specifications of the host should be equipped with digital display, ruler, scale or special mark.

When the design and processing of the host, all the edges and corners are polished, and all the moving parts are designed and installed with protective covers, so as to eliminate potential safety risks and achieve safe production without accidents.

Main engine gas road, circuit wiring specification, no flying line. Automatic protection function; the equipment is installed with an emergency stop button.

The oil-water separator is installed in front of the intake main pipeline to prolong the service life of the pneumatic element; the main engine has air pressure protection alarm device, when the air pressure is too high or too low, the main engine automatically alarm and stop (all the above alarm are touch screen display and alarm lamp sound and light alarm at the same time);

Main technical parameters:

| Overall size (length, X, width, X, height) mm: | 2,000 X1200X2000 |

| Number of cover heads: | 1 head |

| Applicable lid: | customized according to customer request |

| Production capacity: | about 1,800 b / h |

| Pass rate of rotary cover: | 99.90% |

| Power supply power: | AC380V/50Hz;5.5kW |

| Air source pressure: | 0.6MPa |

We firmly believe that through our efforts and innovation, we can bring more surprises to our customers and jointly create a better future for the industry.