- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

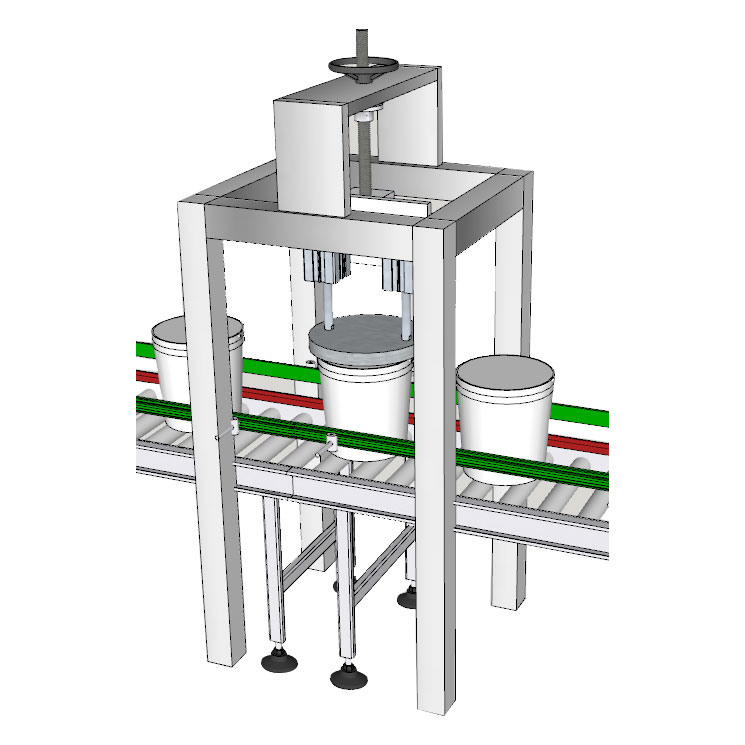

Waterproof Cap Capping Machine

As a well-known supplier in the packaging machinery industry, Somtrue focuses on providing customers with a variety of automated packaging equipment, such as Waterproof Cap Capping Machine. Adhering to the concept of innovative, efficient and stable product development, the company is committed to meeting the demand for packaging machinery on various production lines. Among them, the waterproof cap capping machine as one of the company's advantages, it with its excellent sealing performance and easy operation, favored by the majority of customers.

Send Inquiry

Waterproof Cap Capping Machine

(The appearance of the equipment will vary according to the customized function or technical upgrade, subject to the physical object.)

As a well-known supplier in the industry, Somtrue focuses on providing customers with comprehensive Waterproof Cap Capping Machine. Relying on strong technology research and development strength and manufacturing capacity, the company produces all kinds of efficient and stable packaging equipment, including waterproof cap capping machine for ensuring product tightness. This machine combines automation technology with precision mechanical design to effectively complete the automatic capping and capping process, ensuring that each container can be sealed in place, greatly improving the waterproof performance of the package.

This machine is specially designed for waterproof cap sealing of 200kg drums and is an automatic capping machine. The main machine part adopts stainless steel outer frame, which automatically completes cap picking, drum mouth positioning and waterproof cap sealing. This machine adopts automatic mouth positioning, programmable controller (PLC) for control, touch screen operation, which has the features of convenient operation, high production efficiency, wide range of application, strong control ability and high degree of automation.

The hopper automatically finishes the cap sorting and conveys it to the capping head. When the barrel is conveyed to this station, it can automatically search for the mouth and locate it, and the capping head can automatically pick up the outer cap and press the outer cap on the mouth of the barrel.

Main technical parameters:

| Overall dimensions(L×W×H)mm: | 1200×1800×2500 |

| Number of workstations: | 1 workstation |

| Production capacity: | 200L, about 60-100 barrels/hour. |

| Applicable barrel type: | 200L or so regular round barrels |

| Applicable waterproof cover: | plastic round waterproof cover |

| Power supply: | AC380V/50Hz; 2.5kW |

| Air pressure: | 0.6MPa |