- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Supporting Equipment In Filling Production Line

- Material Conveying System

- Chemical Liquid Filling Machine

- Dangerous Goods Liquid Filling Machine

- New Energy Liquid Filling Machine

- Lithium Battery Liquid Filling Machine

- Large Barrel Liquid Filling Machine

- Pharmaceutical Liquid Filling Machine

- Resin Liquid Filling Machine

- Paint And Coating Filling Machine

- Chemical Filling Machine

- Filling Machine

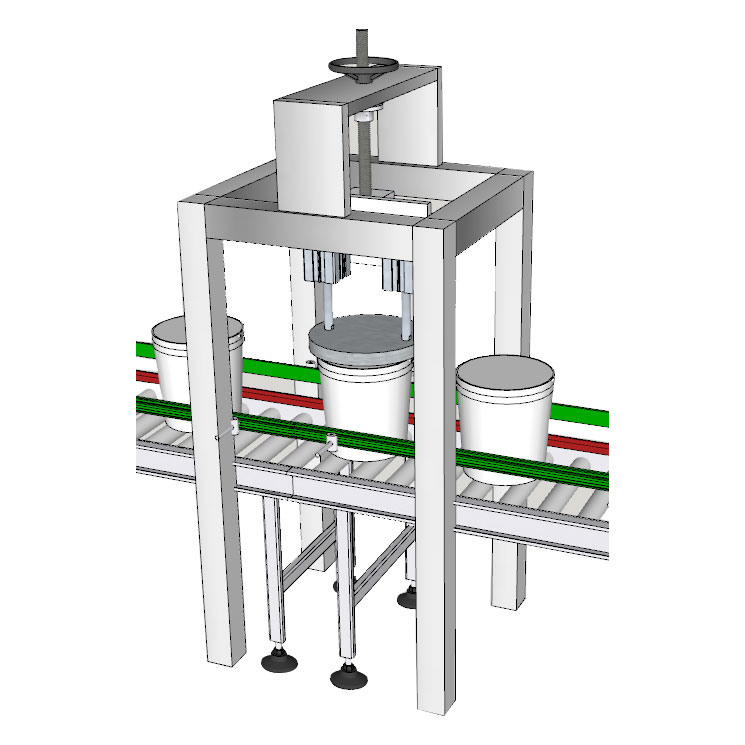

Servo Tracking Screwing Machine

Somtrue is an enterprise focusing on the development and manufacturing of Servo Tracking Screwing Machine, and is committed to providing comprehensive automation solutions. Servo tracking screwing machine is one of its star products, which uses advanced servo motor drive system to achieve high efficiency cap placement and tightening work. This capping machine has a high precision tracking system and flexible adaptability, can be applied to a variety of different specifications and shapes of the cap, to ensure that the capping process is stable and reliable. Its intelligent operation interface makes parameter adjustment simple and fast, greatly improving production efficiency and product quality, while reducing labor intensity.

Send Inquiry

Servo Tracking Screwing Machine

(The appearance of the equipment will vary according to the customized function or technical upgrade, subject to the physical object.)

Somtrue is a professional manufacturing enterprise, committed to providing customers with high quality Servo Tracking Screwing Machine and services. Among them, the servo tracking screwing machine is a main product of Somtrue. The equipment adopts advanced servo control technology, has the advantages of high speed, high precision, high reliability, etc., can help customers better solve the problem of capping in production. We have many years of experience and technology accumulation in product development and manufacturing, and can provide customers with first-class products and perfect after-sales service.

This Servo-Tracking Screwing Machine is the latest model of capping machine carefully designed by our company, introducing the advanced technology of capping from abroad, together with the in-depth research and development of our technical group, the overall performance of the product has reached the international advanced level, and part of the performance has exceeded the best level of the same kind of products from abroad, and it has been recognised by the world's giant companies. It adopts PLC and touch screen automation control, featuring accurate capping, advanced structure, smooth operation, low noise, wide range of adjustment, fast production speed, dynamic capping, etc. PLC is equipped with memory function, which can memorise many kinds of operation parameters at the same time, and the mechanical structure is simple, with large space, equipped with safety protection frame, which improves the safety performance of the whole machine.

The capping head of the capping department is equipped with torque effect control system to ensure the capping effect and avoid the injury of the cap: the capping head is equipped with a clutch device, the capping tightness is adjustable, and when the cap is tightened, the clutch can avoid the phenomenon of injuring the cap and the bottle and prolong the service life of the capping head;

The speeds of bottle feeding, capping, bottle feeding, capping and capping can be adjusted in the touch screen, avoiding the phenomenon of bottle pouring and blocking due to the uncoordinated speeds, and improving the working efficiency; the material of bottle clamping with bottle part is flexible, suitable for most of the shapes of the containers, and eliminating the phenomenon of damage and injury to the bottles; the high-performance and reliable mechanical capping device ensures that the cap feeds into the cap smoothly, softly and without scratches, and Ensure the accuracy of cap positioning.

When normal power on, the host does not work when there is no bottle or few bottles, and it will work automatically after meeting the conditions; after blocking bottles, the host will shut down automatically, and it will work automatically after meeting the conditions. When there is no cap, the mainframe will stop automatically and work automatically after meeting the conditions.

All parts of the host that need to be adjusted for changing specifications are installed with digital display, ruler, scale or special mark.

When designing and processing the mainframe, all the edges and corners are polished, and all the moving parts are designed and installed with protective covers to eliminate potential safety hazards and achieve safe production without accidents.

The air circuit and electric circuit of the main machine are arranged in a standard way. With automatic protection function; equipment installed with emergency stop button.

There is an oil-water separator installed in front of the main air inlet pipe to prolong the service life of pneumatic components; the host has an air pressure protection alarm device, when the air pressure is too high or too low, the host will automatically alarm and shut down (all of the above alarms are displayed on the touch screen and the alarm light sound and light alarm at the same time);

Main technical parameters:

| Overall dimensions (LXWXH) mm: | 2000X1200X2000 |

| Number of capping heads: | 1 head |

| Applicable caps: | according to customer requirements |

| Production capacity: | about 2000-2400 barrels/hour |

| Capping pass rate: | 99.9 |

| Power supply: | AC380V/50Hz; 5.5kW |

| Air pressure: | 0.6MPa |

Somtrue focuses on technological innovation and quality management, and constantly promotes the upgrading and improvement of products to meet the changing needs of customers. In addition to servo tracking screwing machines, the company also offers various other types of equipment, such as filling machines, labeling machines, etc., to provide customers with a full range of production solutions. Somtrue will, as always, adhere to the concept of "quality first, customer first" to create greater value and benefits for customers.